Why Every Fibre Optic Manufacturer Needs an Optical Fibre Diameter Analyser for Quality Control

Why Every Fibre Optic Manufacturer Needs an Optical Fibre Diameter Analyser for Quality Control

Blog Article

Recognizing the Performance of an Optical Fibre Diameter Analyser in Modern Manufacturing

The optical Fibre Diameter analyser offers as a critical tool in contemporary manufacturing, offering specific, non-contact dimensions that are necessary for preserving stringent sector criteria. By leveraging sophisticated laser innovation, these analysers not just guarantee very little signal loss however also boost the total performance of optical fibres. Additionally, their capability for real-time data processing permits suppliers to swiftly address any type of deviations from requirements, fostering a society of continuous improvement. Understanding the ins and outs of this technology increases concerns regarding its wider implications in manufacturing effectiveness and high quality control across numerous sectors.

Significance of Optical Fibre Dimension

In modern manufacturing, the dimension of optical Fibre Diameter is important for making certain the performance and reliability of Fibre optic systems. Exact Diameter measurement directly influences optical performance, as variations can cause boosted signal loss, reduced transmission capacity, and decreased total performance. The optical buildings, including light transmission and signal honesty, are extremely delicate to the Fibre's Diameter, requiring precise control during production.

Moreover, standardization in Fibre Diameter is crucial for compatibility and interoperability within diverse telecoms networks. As these networks expand worldwide, preserving uniformity in Fibre characteristics advertises seamless assimilation across numerous components and systems. Additionally, adhering to market criteria worrying Diameter tolerances is important for producers to fulfill governing requirements and client assumptions.

Spending in advanced measurement innovations not only enhances making effectiveness yet likewise supports quality control processes, allowing manufacturers to recognize issues early in production. This positive method reduces waste and guarantees that the final items meet rigorous performance requirements. The value of optical Fibre measurement can not be overstated, as it serves as a foundation for high-quality, trusted Fibre optic systems, which are important to modern-day communication framework.

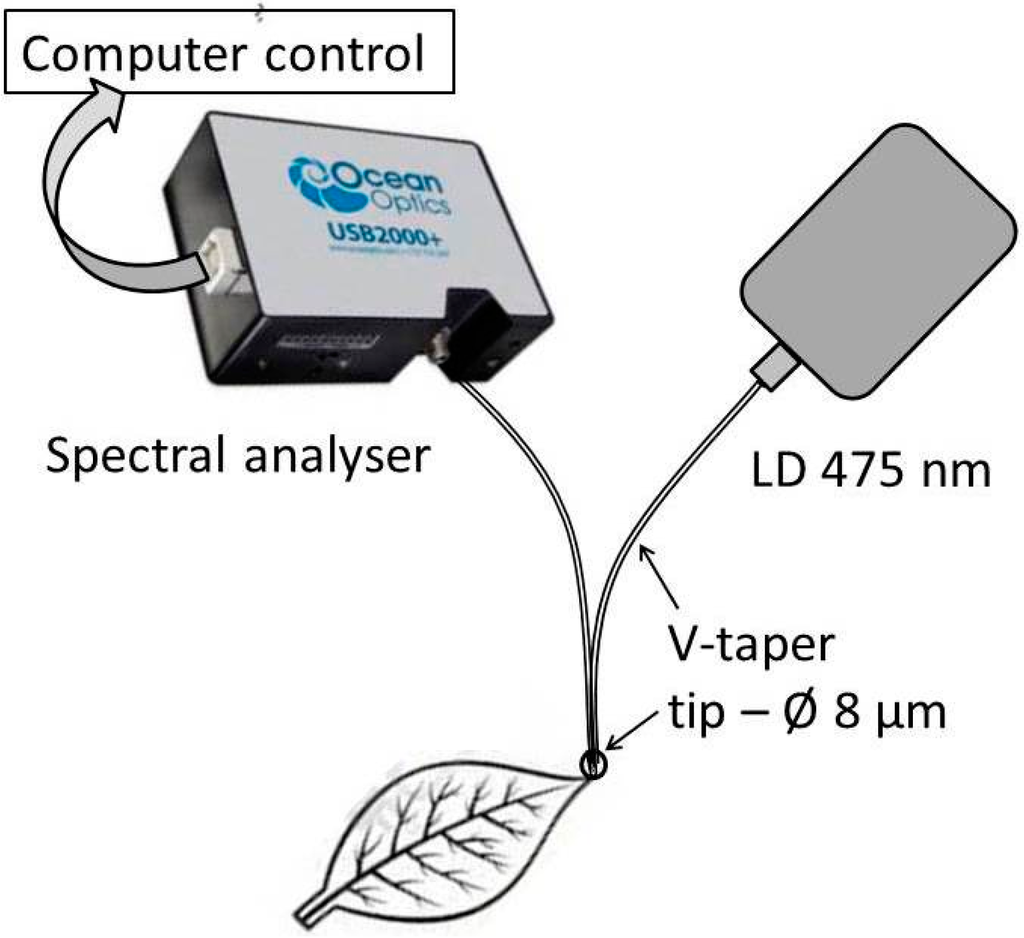

How Diameter Analysers Work

The core procedure depends on the concept of light spreading and reflection. As the laser beam strikes the Fibre, variations in Diameter reason modifications in the light's strength and wavelength (optical fibre diameter analyser). This data is processed in real-time using advanced formulas that equate the optical signals into specific Diameter measurements

Furthermore, lots of Diameter analysers are outfitted with numerous dimension factors along the Fibre, enabling for an extensive analysis of Diameter consistency. The execution of such modern technology considerably improves quality control in production, making certain that optical fibers are produced to specific specs for ideal efficiency in their designated applications.

Secret Functions to Consider

When picking an optical Fibre Diameter analyser, a number of vital functions call for cautious factor to consider to ensure optimum performance and reliability. Initially, dimension precision is extremely important; the analyser must offer accurate Diameter readings, typically in micrometers, to satisfy rigorous manufacturing requirements. Furthermore, a wide measurement variety enhances convenience, accommodating numerous Fibre types and thicknesses.

An additional crucial feature is the analyser's speed. Quick dimension capacities permit increased throughput, vital in high-volume manufacturing atmospheres. Furthermore, real-time information handling and comments abilities enable immediate changes, enhancing quality assurance.

Individual user interface and software compatibility are likewise significant considerations. A straightforward user interface simplifies procedure, while durable software application support helps with information analysis and assimilation with existing production systems. The capacity to export information in numerous layouts can improve reporting and compliance initiatives.

In addition, resilience and maintenance demands ought to be evaluated. An analyser created from premium materials will certainly withstand the rigours of a manufacturing environment, while ease of upkeep makes sure durability and minimizes downtime. Finally, consider the level of technological assistance and training provided by the supplier, as this can considerably affect the effective usage of the analyser in production setups.

Benefits in Production Efficiency

Enhancing production effectiveness depends upon the integration of sophisticated modern technologies, such as optical Fibre Diameter analysers. These instruments play an essential role in making certain that optical fibers fulfill stringent quality criteria, which is vital for optimal performance in different applications - optical fibre diameter analyser. By offering real-time dimensions of Fibre Diameter, makers can swiftly determine and remedy deviations from defined resistances, consequently lowering waste and reducing the threat of malfunctioning items

Furthermore, the early detection of prospective issues causes decreased downtime and upkeep costs, thereby optimizing resource allotment. Inevitably, the efficiency obtains understood via using optical Fibre Diameter analysers add to an extra affordable manufacturing atmosphere, ensuring that companies can provide high-quality items while preserving cost-effectiveness and responsiveness to market needs.

Applications Across Industries

The versatility of optical Fibre Diameter analysers expands beyond producing efficiency, discovering applications throughout different markets that rely upon optical Fibre modern technology. In telecoms, these analysers are crucial for guaranteeing the ideal performance of Fibre optic wires, straight influencing information transmission prices and network reliability. By accurately gauging Fibre sizes, operators can lessen signal loss and enhance total interaction quality.

The clinical sector likewise profits substantially from these gadgets, specifically in the growth of endoscopic devices and laser therapies. Specific Diameter dimensions are crucial for producing Homepage efficient optical fibers that are made use of in minimally invasive treatments, enhancing client end results through improved imaging and therapy capacities.

In aerospace, the analysers play an important function in the manufacturing of lightweight, high-strength products, where Fibre optics are Discover More incorporated into architectural parts for surveillance and diagnostics. Furthermore, the auto market employs these gadgets to make certain the integrity of Fibre optic sensors that boost safety and efficiency attributes in cars.

Final Thought

In conclusion, the optical Fibre Diameter analyser is essential for contemporary manufacturing, making certain accurate measurements that maintain industry criteria. The diverse applications across various industries underscore the analyser's relevance in advertising constant enhancement and data-driven decision-making within the production field.

In modern-day manufacturing, the dimension of optical Fibre Diameter is vital for ensuring the performance and reliability of Fibre optic systems. The value of optical Fibre dimension can not be overemphasized, as it serves as a foundation for top notch, reliable Fibre optic systems, which are indispensable to modern interaction infrastructure.

Diameter analysers utilize innovative optical technologies to accurately from this source measure the Diameter of optical fibers.In addition, lots of Diameter analysers are furnished with multiple dimension points along the Fibre, enabling for an extensive evaluation of Diameter uniformity.The adaptability of optical Fibre Diameter analysers expands beyond making effectiveness, discovering applications across different industries that rely on optical Fibre innovation.

Report this page